Operation, Maintenance, Modification

FSM requirements continue throughout the operation, maintenance and modification phases of the Safety Life Cycle. Particularly for legacy plant, there may be gaps in FSM activities, ranging from minor documentation issues up to potential degradation of SIF-function due to inadequate proof testing or exceedance of equipment useful life.

FSM activities throughout the operational life are generally Operator responsibility. PSC can provide independent inspection and auditing services, witnessing, expediting, preparation of documentation such as proof test procedures, etc. and will prepare corresponding reports and documentation as required. Particularly for existing plant, there may be gaps regarding FSM compliance.

For existing systems, PSC can provide following services:

- Compliance review of ‘legacy’ safety systems

- Closure of FSM documentation ‚gaps‘

- HRA revalidation (‚Re-HAZOP‘)

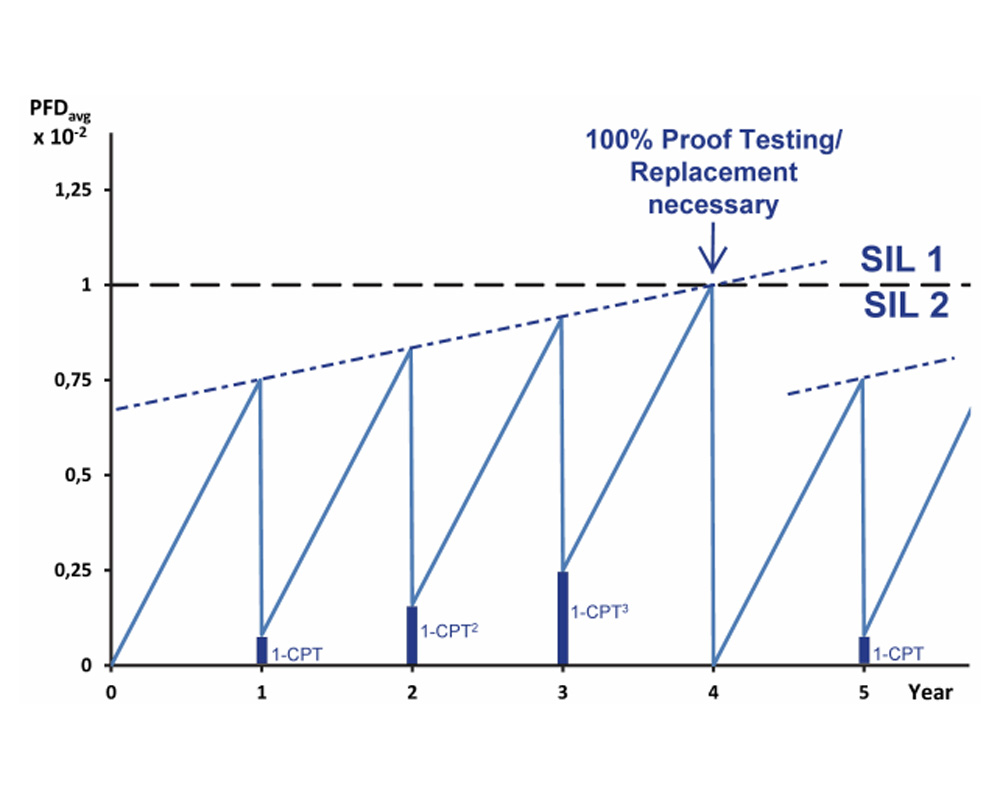

- Review of Proof Test procedures and definition of corresponding CPT

- Independent evaluation of Site Safety Index (SSI)

- Evaluation of ‚SIL-Degradation‘ due to incomplete proof testing and end of useful life

- Proven-In Use justification

- Cost-benefit analysis of SIF modifications

- Update of SRS to ‘as-built’ status

- Review or set-up of KPIs

- Collection and analysis of operational data as per IEC 61511-1 §16.2.2