NET4GAS is the natural gas Transmission System Operator (TSO) in the Czech Republic. The company operates more than 3,800 km of pipelines, as well as associated facilities including three border transfer stations, four compressor stations and nearly one hundred meter/regulating stations.

PSC has to date carried out ten HAZID / HAZOP / SIL studies and updates for various NET4GAS facilities (formerly RWE Transgas NET), starting with the Gazelle Pipeline and Stations in 2009. The latest HAZOP, completed in March 2018, covered a planned new DN 1400 natural gas high pressure pipeline (HPPL) and facilities which form part of the Capacity4Gas Project. In order to streamline the workshop and make use of previous similar HAZOPs with the same core Client/Designer Team, PSC used the ‘HAZOP by Difference’ methodology (also called Delta-HAZOP).

In contrast to the ‘full HAZOP’, the ‘HAZOP by Difference’ technique is used to analyse changes compared to an existing system or previous HAZOP. ‘HAZOP by Difference’ is done by reviewing the individual proposed new changes to ensure that the hazards of the process are understood and that adequate controls are in place to manage these hazards. This effort may also require a complete HAZOP analysis for specific aspects that the Team considers need to be addressed.

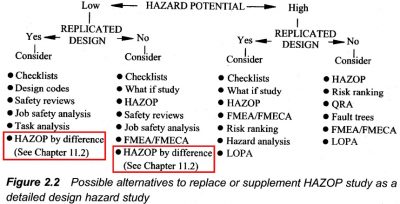

‘HAZOP Guide to Best Practice’, Figure 2.2, gives guidelines as to when ‘HAZOP by Difference’ technique can be used, depending on degree of repeat design and any other significant changes such as size, site, services and interfaces with other plant.

Source: ‘HAZOP Guide to Best Practice’, 2nd edition, © 2008 European Process Safety Centre (permission granted)

Parallel, IEC 61511 recognises the need for HAZOP update during the Safety Life Cycle (e.g. section 17.2.5 defines the requirements in the case of SIF-modification). Even if there has been no modification, many jurisdictions require HRA to be re-visited during the lifetime of a plant, e.g. EPA/RMP and OSHA/PSM in the US, MHF in Australia and COMAH in UK require update every five years. ‘HAZOP by difference’ is a useful technique for this type of Revalidation, however, needs to be used with care. Industry standards (such as BP ETP GP 48-02 Annex C) give additional guidelines to evaluate the applicability of HAZOP revalidation technique.