Hazard and Risk Assessment (HAZOP, FTA, QRA)

The first step of the Safety Life Cycle is a Hazard and Risk Assessment (HRA) to determine the risks associated with a particular plant or process. Level of analysis can range in complexity from ‘What if’ Checklist to HAZOP, FMEA, FTA up to QRA.

All HRA’s follow a structured methodology to identify hazards present in the plant, evaluate the corresponding risk and establish any mitigation measures to reach an acceptable level of residual risk. The level of analysis can vary from simple ‘What if’ Checklists, through HAZOP up to a detailed Quantitative Risk Analysis depending on the complexity of the Plant and the type of risks to be analysed. For more detailed theoretical analysis, techniques such as FMEA (Failure Modes and Effects Analysis) and FTA (Fault Tree Analysis) can be used.

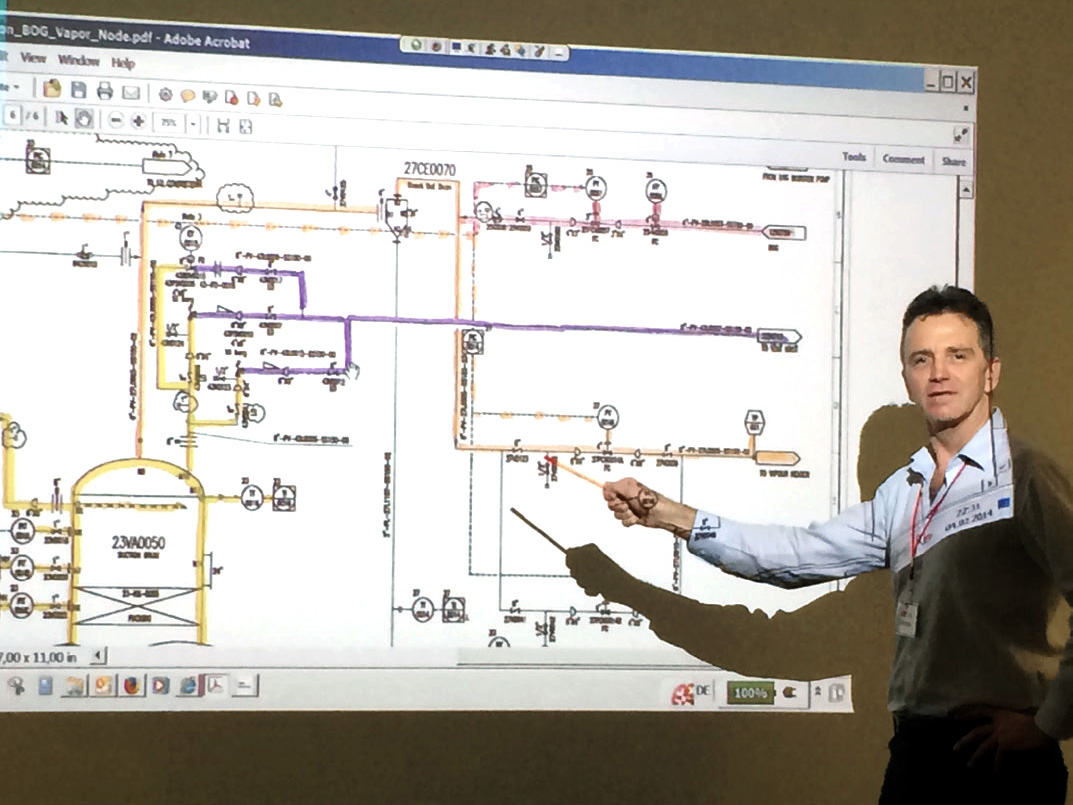

HAZOP is generally the most suitable qualitative method for analysis of plants of medium complexity. During a HAZOP study, the hazards are identified in a structured way by an experienced multi-disciplinary team including design engineers, operators and safety experts. The HAZOP workshop is moderated by an independent, qualified Chairman who follows a standard framework of ‘Guide Words’ to initiate brainstorming by the Team. Safeguards already provided in the design are evaluated in terms of their ability to reduce frequency or consequence of the identified hazards. If remaining risks are identified as high or even in ALARP range, a recommendation is made to determine if the risk can be further reduced, or preferably eliminated.

Although HRA is carried out during the initial design phase of a project, many jurisdictions require such studies to be re-visited during the lifetime of a plant, e.g. EPA/RMP and OSHA/PSM in the US, MHF in Australia and COMAH in UK require update every five years. Special techniques are used for such ‘Revalidation’ such as ‘HAZOP by difference’.

PSC has provided independent Chairman and Scribe services for over eighty HAZID, HAZOP (including HAZOP revalidation) and LOPA studies both nationally and internationally. PSC experts are certified according to IChemE and the Exida CFSE program. Depending on the project, PSC uses proprietary software such as PHA Works, ExSILentia, or in-house excel templates. For more detailed risk analysis, tools such as PHAST, SAFETI and FaultTree+ may be used to provide a quantitative basis for FMEA, FTA or QRA.