HAZOP-Update, SIL-Verification for Compressor Station Legacy Systems

Projectowner:

Confidential

Timeframe:

2017 – 2018

Key Project Data:

Existing gas transport compressor station, in operation since ca. 10 years, comprising:

- Electric-motor-driven (EM) gas compressor

- Gas-turbine-driven (GT) gas compressor

- Pipeline interconnections, including metering stations

- Tie-in of new pipeline and over-pressure protection systems (under construction 2018)

- Existing station auxiliary and utility systems, including three independent legacy safety systems (Station, EM-compressor, GT-compressor)

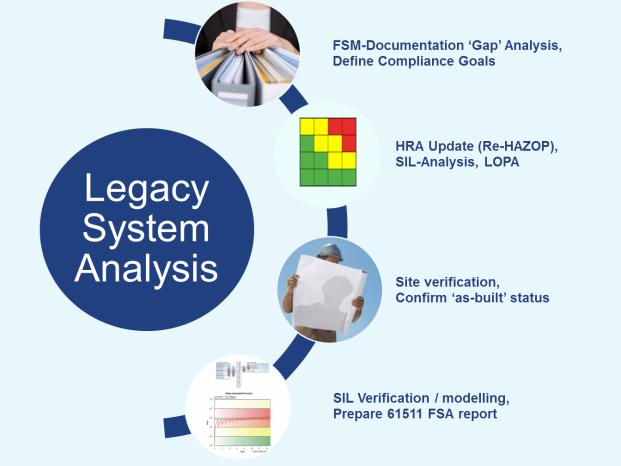

Scope of Services:

- Update of HRA (re-HAZOP) and SIL-analysis (Risk Graph method acc. VDI/VDE 2180)

- Gap analysis of existing FSM-documentation

- Preparation of Cause & Effect Chart for safety and process trip logic

- Investigations on site to confirm as-built status of safety-related loops

- SIL-Verification using ExSILentia and preparation of compliance report (equivalent to FSA-4) according to DIN EN 61511:2012

- Preparation of recommendations and priorities for implementation

All services were carried out in accordance with PSC’s FSM-Plan as per DIN EN 61511 and CFSE-certified.

Extended Description

The following gives a detailed description of PSC‘s services.

Existing safety review was updated on basis of as-built status. The update was carried out via several workshops covering following nodes:

- Station main process systems

- Station auxiliary systems (vent, fuel gas, fire & gas system)

- Flow path variations (ca. 50 station operating modes investigated)

- Compressor-driver units, including auxiliaries

- Tie-in of new pipeline and over-pressure protections

SIL / Risk reduction analysis carried out as per calibrated Risk Graph methodology (VDI/VDE 2180). 70 safety loops investigated, resulting in definition of SIL/RRF for 34 SIFs.

Review of legacy documentation established that some FSM-documents should be updated, e.g.

- Cause & Effect Chart

- Safety Requirements Specification

- Sensor / actor failure data/ certification

Modelling of SIFs using ExSILentia software

- Review of available E&I, safety system logic and vendor documentation and confirmation of ‘as-built’ status via site inspections

- Database research / contact to manufacturers to establish failure data for legacy equipment with missing certification

- Evaluation of ‘proven-in-use’ capability where published failure data was not available

- Review of site proof-test procedures in order to define CPT for all SIFs

- Modelling of loops in ExSILentia and preparation of compliance documentation

- Recommendations based on identification of FSM-compliance issues:

- SIL-degradation

- End of equipment useful life

- Proof test coverage

- Management of non-SIL functions implemented in safety systems