IEC 61511 recognises the need for HAZOP update during the Safety Life Cycle. Even without plant modification, it is recommended to update HRA every five years. With time on its hands, the PSC-Team decided to update the HAZOP of Death Star 1.

Many persons of a certain age remember the impact of George Lucas’s original Star Wars when it arrived in movie theatres in 1977. Over forty years later, many engineers of a certain age are still obsessed with the technical details of the film. As the PSC-Team considered how to best utilise its time during Corona-lockdown, a priority activity was to refresh our ‘Procedure for HAZOP / LOPA via video conference’. As subject matter, we chose to revalidate the HAZOP for Death Star 1, the moon-sized, deep-space mobile battle station constructed by the Galactic Empire, that appears in the first Star Wars Film. Unsurprisingly, there have been a number of previous efforts to carry out risk analysis of the Death Star, in an attempt to reveal its fatal flaw. The PSC-Team chose the following paper as basis for the revalidation (What the Death Star can tell us about Ergonomics Methods).

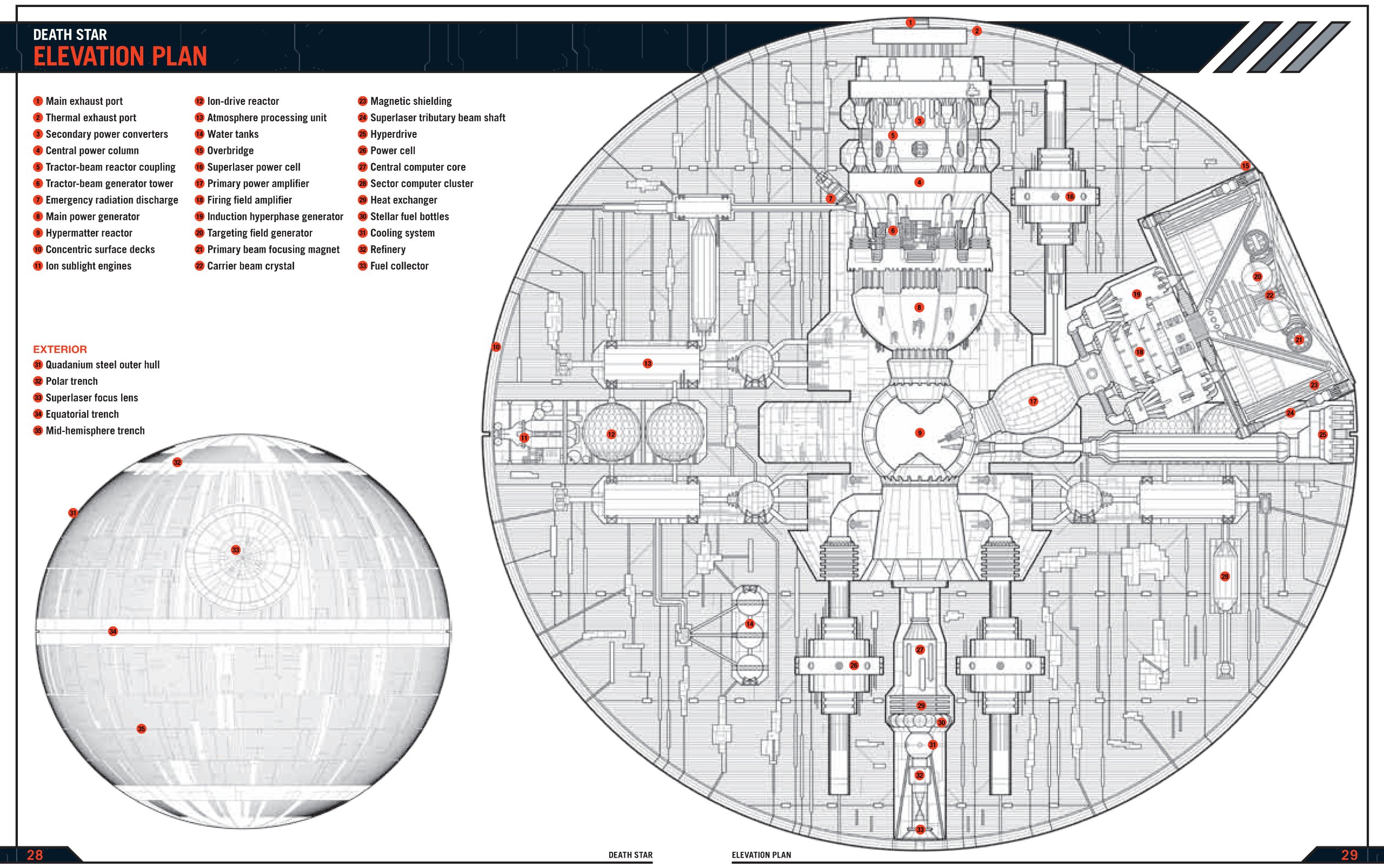

Source: Haynes Imperial Death Star Manual

Here are some of the HAZOP-Update highlights:

- Previous Risk Analysis migrated to ExSILentia

- Node re-hazopped using the procedural guideword technique:

- Thermal exhaust port – Expel excess energy (Task Step 2.1.1.5)

- Operational ‘lessons learned’ reviewed at the start of the Workshop:

- DS-1 five-years successful operation, including 14 planets destroyed and 22 Rebel Alliance attacks repelled

- Maintenance budget constraints were identified as a concern

- Nuisance alarms have been temporarily bridged

- Previous HRA recommendations were reviewed and ‘closed-out’

- Risk ranking (missing from the previous HRA) was carried out to determine if existing safeguards were sufficient

- Additional causes were identified, analysed and new recommendations made

The Team concluded that the HAZOP update technique per IEC 61511 was an appropriate method for analysing the hazards of a 120km-diameter galactic superweapon. Despite 5-years operational experience, risk ranking identified further actions. Lack of original design assumptions and inadequate as-built documentation limited the HAZOP update effectiveness.

PSC has provided independent Chairman and Scribe services for >100 HAZID, HAZOP (including HAZOP revalidation) and LOPA studies. PSC experts are certified according to IChemE and the Exida CFSE program. Please download our DS-1 HAZOP Update report here.

Spoiler: HAZOP-Update did not reveal the ‘fatal flaw’