Set-Up of a Functional Safety Management System (FSMS)

Projectowner:

Turnkey Contractor (chemical / pharmaceutical plant), Germany

Timeframe:

2019/2020

Key Project Data:

A medium-sized Turnkey Contractor (annual turnover 25 Mio. EUR) requested assistance to set up a Functional Safety Management System in accordance with IEC 61511-1.

Scope of Services:

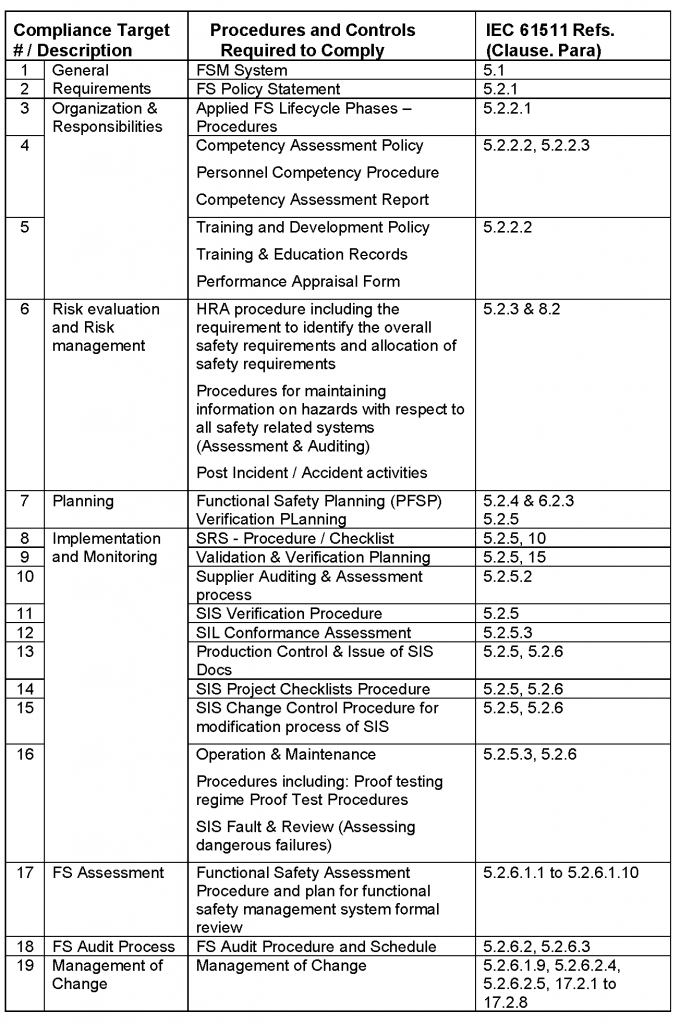

PSC provided consultancy services to set-up a FSMS that was tailormade to the engineering, fabrication and installation activities of the Turnkey Contractor.

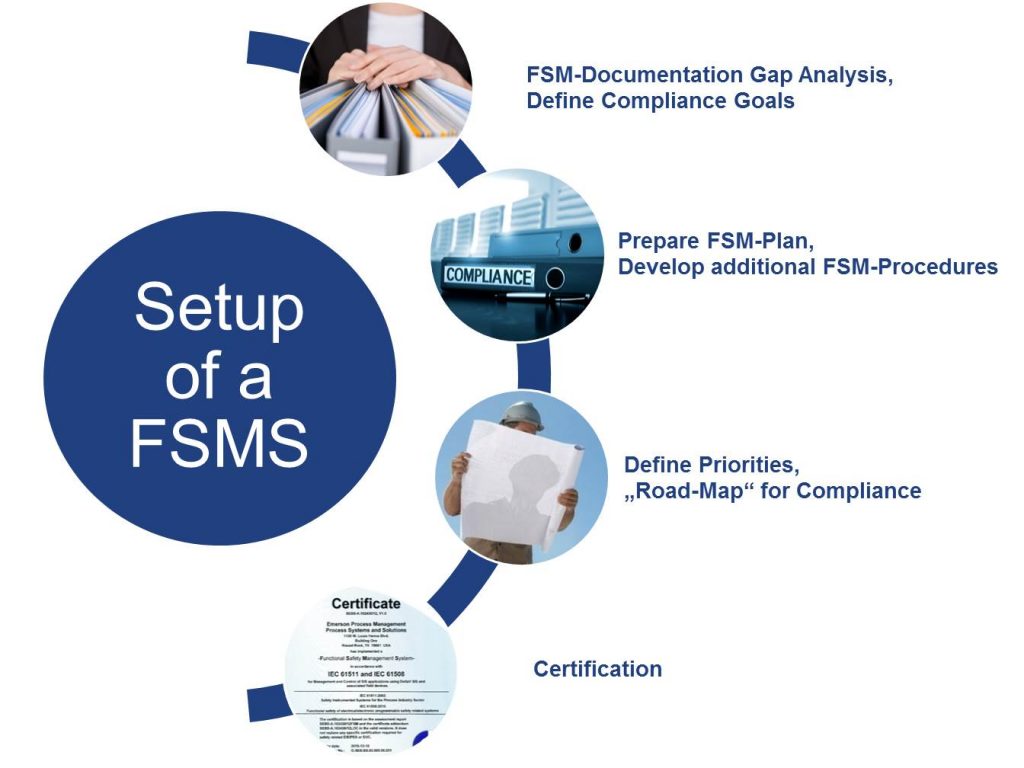

The project comprised three stages:

1.Gap Analysis acc. IEC 61508/61511 Checklists

- Desk-top-Review of existing FSM-, QM-Procedures

- Compliance-Review and Interviews acc. to Checklist at Contractor premises

- Management Report, Presentation/Discussion of Recommendations

2.Preparation of the FSMP

- FSM-Plan: Table of Contents, Scope

- Preparation of SLC Responsibility Matrix and Activities

- Pragmatic way forward, cross-reference / integration of existing QM-Procedures

- Define Priorities for the next steps: training requirements, preparation of missing documentation/procedures

- “Road-Map” for phased Compliance

3.Preparation of FSM-Templates

- Preparation of 24 templates

- Intensive comment / review sessions to adapt templates to Turnkey Contractor scope and responsibilities as per IEC 61511